Contstruction Machinery Industry

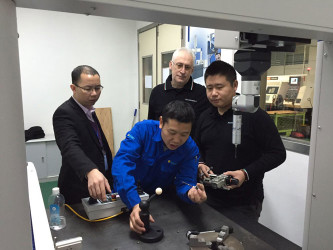

Sicoma Zhuhai (Cina)

Complete production layout redesign in an existing factory. Design and start-up of one concrete mixers assembly line. Product reengineered in order to perform machine tool operations before welding. Implementation of the World Class Manufacturing (WCM) approach.

SOCAGE

Industrial Vehicles Factory

Socage

Reorganization of the production process. Optimization of the welding process. Design of welding tools. Manufacturing drawings delivered to the customer. Support in solution of supplier quality problems.

CAB PLUS IMOLA

Earthmoving Machinery Industry

Cab Plus Imola

Complete production layout redesign in an existing plant. Design and implementation of an assembly line to produce earth-moving machine cabs.

FERRI S.r.l.

Agricultural and Off-Highway Machinery Industry

Ferri S.r.l.

Storage layout redesign, study and implementation of special storage equipment. Production layout restructure, from stations to line. Study and design of the automated line conveyor. Machine tools layout optimization. Analysis and reduction of the process losses due to supplier quality problems.

Agricultural and Off-Highway Machinery Industry

Aries S.r.l. Tiberina Group

Complete redesign of the production layout in a new plant. Optimization of available tooling and new tooling design. Design and implementation of an assembly line with 100% final testing, including the study of handling and lifting equipment. Design and implementation of an ironwork assembly line with welding robots, design of the weld tooling. Study of an automated sheet metal storage system to feed a laser cutting unit.

Construction Machinery Industry

O.M.G. S.r.l.

Complete production layout redesign in an existing plant. Design and start-up of two concrete mixers assembly lines. Design of the layout of a new production unit with assembly lines. Innovative study of a fully automated painting plant with painting robots. Implementation of the World Class Manufacturing (WCM) approach. Process losses reduction project: 30% in one year. Assembly lead time reduction from 20 to 6 hours.

CAB PLUS JESI

Industrial Vehicles Factory

Cab Plus Iesi

Redesign of production process and layout.Design and implementation of an assembly line to produce earth-moving machine cabs. Implementation of a lean production system. Production increase by 20% in 15 days. Ironwork assembly line start-up. Welding and sheet metal forming processes optimization. Design from scratch of an automated factory with component handling by laser-guided vehicles.